Disclosure: I sometimes earn products or commissions from affiliate links or partnerships on my blog. I only recommend products and services I trust to serve you. Learn more.

Choosing the right mortar mix for your cordwood masonry construction project doesn’t have to be difficult. Here’s how we made ours and what you need to know to make the most of your mortar mix.

I often receive questions from people who are curious about the mortar we use in cordwood masonry construction.

Yes, mortar! Not cement or concrete or stucco or any of the other myriad things it is often mistaken for.

We’re going to show you what cordwood-specific mortars are, how they’re different, and show you our experience with our home’s mortar mix.

What is cordwood masonry?

First, it is imperative to know what cordwood masonry IS. If you’re a complete newbie to this building style, please reference Cordwood for Beginners and the Cordwood Beginners FAQ.

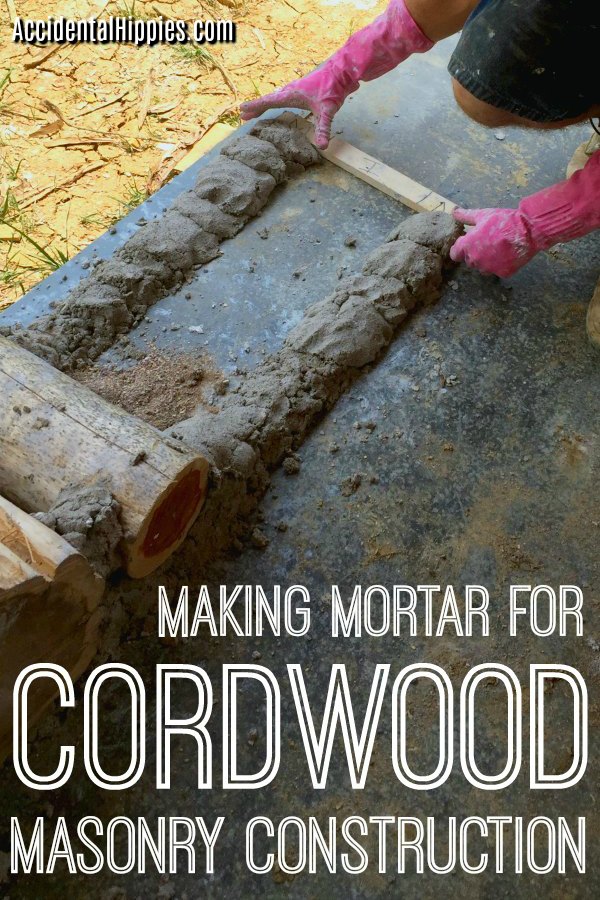

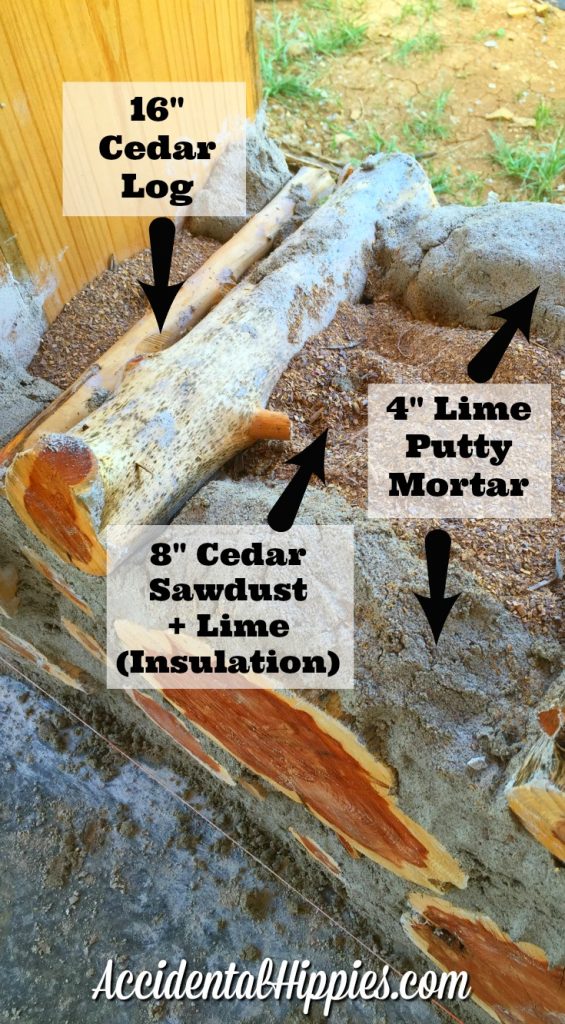

Basically, logs are laid within a bed of mortar with a cavity of insulation in the center like this:

The finished walls end up looking like this:

What is a mortar mix for cordwood masonry, and how is it different from the bagged stuff?

A cordwood mortar mix MUST be slow curing to avoid shrinking away from the logs and creating gaps. A slow curing mix also makes it much easier to “point”, or smooth out the mortar, as you build. This involves smoothing out the mortar with a non-serrated knife. We used old butter knives and found little hors d’oeuvres knives to be the easiest to work with.

The bagged mixes at the hardware store set too quickly and do not provide the kind of structure you’re looking for in a cordwood mortar.

What is your mortar mix made out of?

We used a LIME PUTTY mortar mix. We chose it because it:

- Only has three ingredients.

- Is relatively easy to teach to friends and family who come to help on work days.

- Has the ability to self-heal small cracks.

- Is a brighter white than a Portland mix, which is grayer. We wanted our walls to be bright.

Our lime putty recipe is very simple: 5 parts fine masonry sand to 2 parts lime putty. Water as needed to reach the right consistency.

*The right consistency: if you make a ball of mortar and toss it in the air, it should widen just a little bit when it lands, but not go splat or crumble apart.

How did you get the materials for the mortar?

Sand

For the amount of cordwood we knew we would be building, we knew we needed more sand than what one could fit in the bed of a pickup truck. So we had our friendly excavator friend bring us a tri-axle dump truck load of masonry sand for roughly $300.

We used roughly 3/4 of the sand to build the house. The remainder has affectionately become “the sand pile” for our young son to play in.

Lime Putty

For the lime putty, the most economical option was to get bags of Type-S Hydrated Lime in 50-lb bags at Menards. I have never found this item at any of the other large hardware stores, nor have we found it at smaller local stores. If you do not have a Menards near you, call up your nearest concrete company and ask them if they either can supply it or have references for those that do.

Note: You do not want agricultural lime or any other grade of lime. You need Type-S Hydrated Lime specifically for masonry.

Bigger note: “Hydrated Lime”, despite sounding like a wet thing, is a dry powder and will BURN YOU. It hurts. A lot. Please take care to cover your skin by wearing appropriate clothing, shoes, gloves, goggles, and face mask. If it comes in contact with your skin, brush off as much as you can first, then wash liberally with soap and water. Make sure to have plenty soap and water on hand at your building site. You can get more safety information on hydrated lime here.

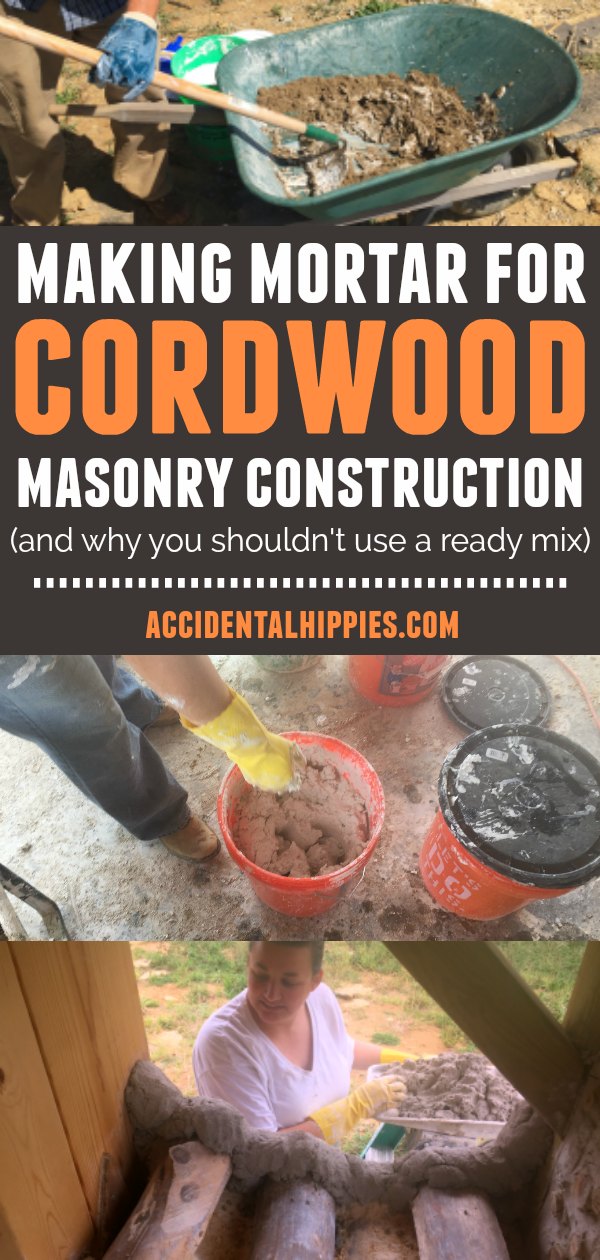

How do you mix your mortar?

We began early in the process mixing it by hand in a wheelbarrow with a garden hoe because that’s what we had. There are mortar hoes that have holes in them to make this job easier, but mixing all of your mortar by hand is still a very tedious and labor-intensive process.

We realized that if we were going to finish our walls before the first frost, we needed to mix faster. To do this, we made a very hasty trip to the hardware store to buy the last electric mixer they had in stock. Lucky us.

Using a mixer greatly increased our mixing speed. That being said, the first mortar that we mixed by hand is some of the best-looking mortar we have in the whole house.

We used the mixer not only for making the mortar, but also for making the lime putty.

We would put some water and lime powder into the mixer and let it mix for a few seconds until it was a consistency like a thin cream cheese. Then we’d empty it into buckets with lids to set for 2-3 days before using. The finished product is strikingly similar to a cream cheese spread. If it’s runny like sour cream you need more lime powder. If it’s hard and looks like cottage cheese, add water because you’ve gone too far…Please don’t eat your lime putty.

What supplies did you use for your mortar?

- Scoops

- Wheelbarrow

- Pans

- Gloves

- Pointing knife

Scoops

Your mortar mix, while somewhat forgiving, still requires an amount of precision when you’re measuring out the ingredients. Since we had two ingredients we got two different colored feed scoops: a red one for the sand and a blue one for the lime putty. They had measuring lines on the inside to help keep us accurate.

Wheelbarrow

Once we’d finish mixing a batch of mortar in the mixer, we’d dump it out into the wheelbarrow and transport it closer to the wall we happened to be working on at that time.

Pans

Each person working on mortar would get a pan to put a generous helping of mortar in. We used some metal paint trays because that’s what we had. Other people have used cake pans, pie plates, and big serving bowls as well. It doesn’t really matter what it is as long as it helps you have mortar close at hand and isn’t something you want to keep “nice”.

Gloves

Our favorite gloves to use are heavy duty cleaning gloves like these.

We loved these because they are waterproof and have a soft inner lining that protects your hands much more from colder working temperatures AND the coarse materials in the mix. We used the lighter duty yellow ones and our hands would be pretty raw at the end of the day, more so than if we used the heavier duty purple ones. They also lasted much longer and resulted in less waste during the build.

We tried some of the fabric gloves with rubber or poly coatings per the recommendation of other cordwood builders, but we did NOT like using these at all. The sand and grit would get in through the top and our hands would just be wet constantly because our hands were often in and out of buckets of water to either clean tools, clean hands, or scoop out some water to moisten a dry mortar mix.

Pointing Knife

Like I said, we used some old butter knives with smooth edges. You could also use frosting spreaders or something similar. It doesn’t have to be fancy. Here’s our son, then age 3, helping to point mortar in what is now the master bedroom.

What are some other mortar mix options?

There are other fine mixes out there. To quote Rob Roy from this excellent Q&A post at Green Homebuilding:

Mix A: 9 sand, 3 soaked softwood sawdust, 3 hydrated (Type s or “Builder’s”) lime, 2 Portland cement. The sawdust should be passed through a half-inch mesh screen and soaked at least overnight.

Mix B: 9 sand, 3 masonry cement, 3 ounces of W.R. Grace Daratard 17 cement retarder.

Richard Flatau also takes time to go through mixes in great detail, as well as to outline the process, in his book Cordwood Construction: Best Practices and in his instructional DVD. I highly recommend both resources to anyone seriously exploring cordwood construction.

How do I choose the best mortar mix for my cordwood building project?

I get a lot of questions from people about whether a certain mortar mix will work for their climate. Usually, they’re worried that it’s either too cold where they live, too humid, too dry, and so on.

For the most part, the mortar you choose is a matter of personal preference. There are some caveats to remember though:

- Lime putty mortars are most susceptible to frost and freeze damage while they set. They should ideally be completed at least 30 days before a freeze to allow time for proper curing.

- All mortars will mix and cure better in warmer weather, plus building cordwood in the cold weather is miserable. If you must build in colder temperatures, take care to protect your walls with blankets and/or plastic sheeting of some kind. You might even try to heat the space if possible, but your best bet is to just NOT build in cold weather.

Other than that, most mortars will work in most places. Choose what works best for you.

What happens if there’s a freeze? Did you experience this?

Yes, we did, but not right away.

We completed our cordwood on October 30th, and it was nearly 80 degrees that day. There was unseasonably warm weather all the way up to that point, though there were mornings where we’d be mixing mortar and it was around 35-40 degrees. Mortar starts to feel and behave quite differently at that point. It becomes difficult and unpleasant.

In the 3-5 days after we finished the walls we continued to have warm temperatures, and then it dropped down into the 20’s and 30’s. The mortar was still curing during that time, and some parts of the surface started to flake off. It was jarring to see. I was certain we’d ruined the wall.

But like I said, lime putty has an ability to self-heal small cracks. Over the next few months, most of that flaking healed itself. I remember where it was and I can’t even find those spots now. That being said, I definitely wouldn’t risk it again. We got lucky. If you have the ability to build your cordwood entirely in warm weather and to take your time doing it, DO THAT.

We documented our entire build from start to finish. Read our step-by-step update posts here.

Curious about our project? We’ve got a complete overview with all of our specs here.

If you’re planning to build your own cordwood house, I recommend taking a look at our Owner-Builder Home Planner to help you maximize your build.

There’s a lot more discussion happening over on Facebook and Instagram too. Join us to learn more about cordwood building, off-grid living, and the journey to self-sufficiency!

This is a great article. When I was younger I bought Roy’s Books (before the internet) and never knew the true recipe. I did not have the funds or time (procrastination and youth) to get to his workshops, but I still have his books. Thanks for posting a detailed article. It looks like there is more. Going to read it all. PEACE!!

Thanks! There is a ton more (and still adding more all the time). Be sure to sign up for the email list (and confirm your subscription!) to get new posts and information as it comes out. Thanks for being here!